|

Dry pressing ceramic is the most economic process for large production runs, and is suitable for both simple and complex geometries. Depressions and holes are normally only designed in the pressing direction.

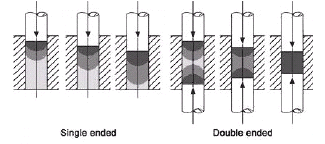

Figure 1. Single axis dry pressing, single and double ended, with regions of different compression (grey levels)

Application of Dry Pressing

Dry Pressing is used to manufacture mass-produced precision ceramic products. Non-clumping granulates are compressed in steel dies designed appropriately for the part to be manufactured. The high cost for the dies (sometimes made of carbide) can only usually be justified for large runs.

Depending on the design of the ceramic dry pressing machine, components ranging in size from tiles down to match heads can be manufactured. Small discs or plates can be pressed with thicknesses of around 0.8 or 1.0 mm. The tape casting process is more suitable for even thinner, flatter components. It is still possible to manufacture fine ridges or similar structures on the component if the granulate being pressed can effectively fill hollows in the pressing tool, and provided it is possible to create the necessary tool. |